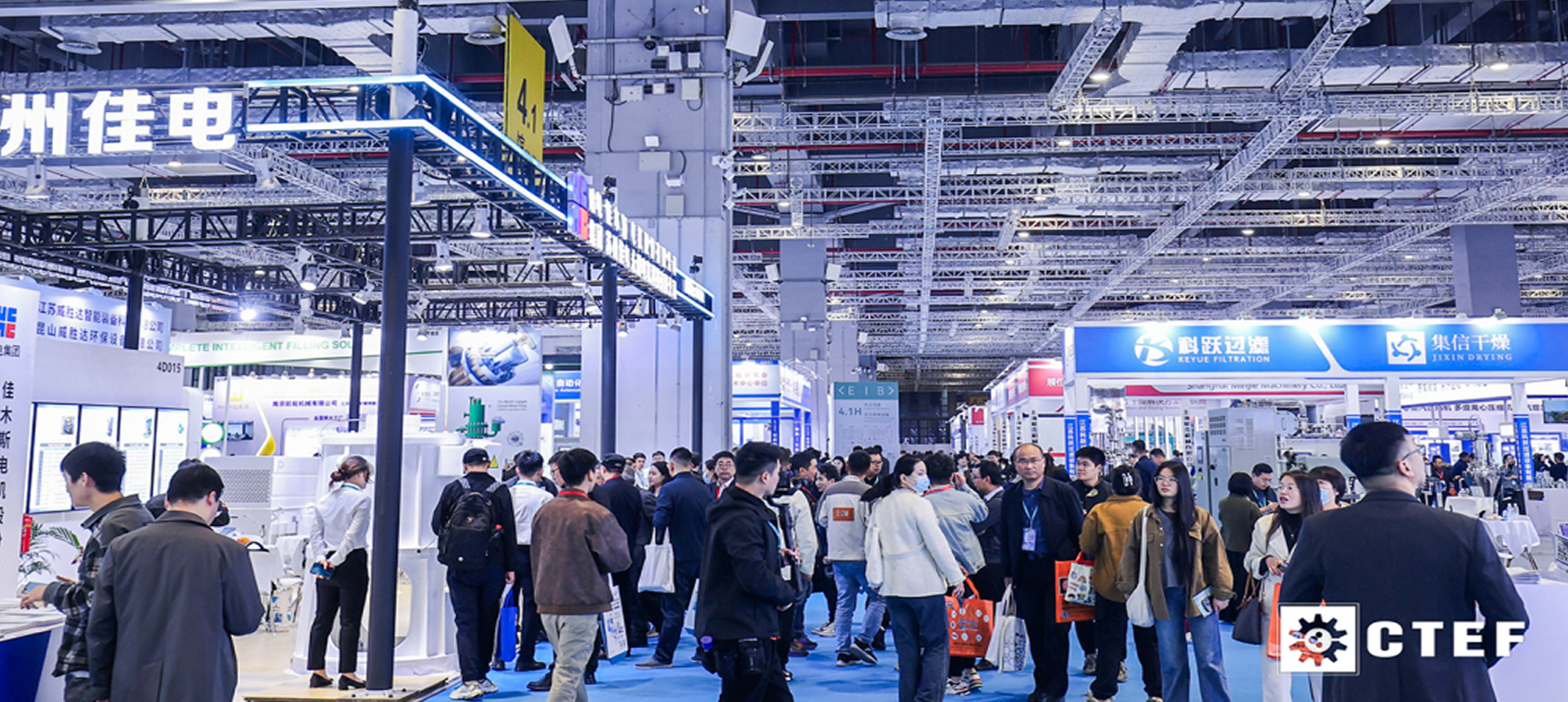

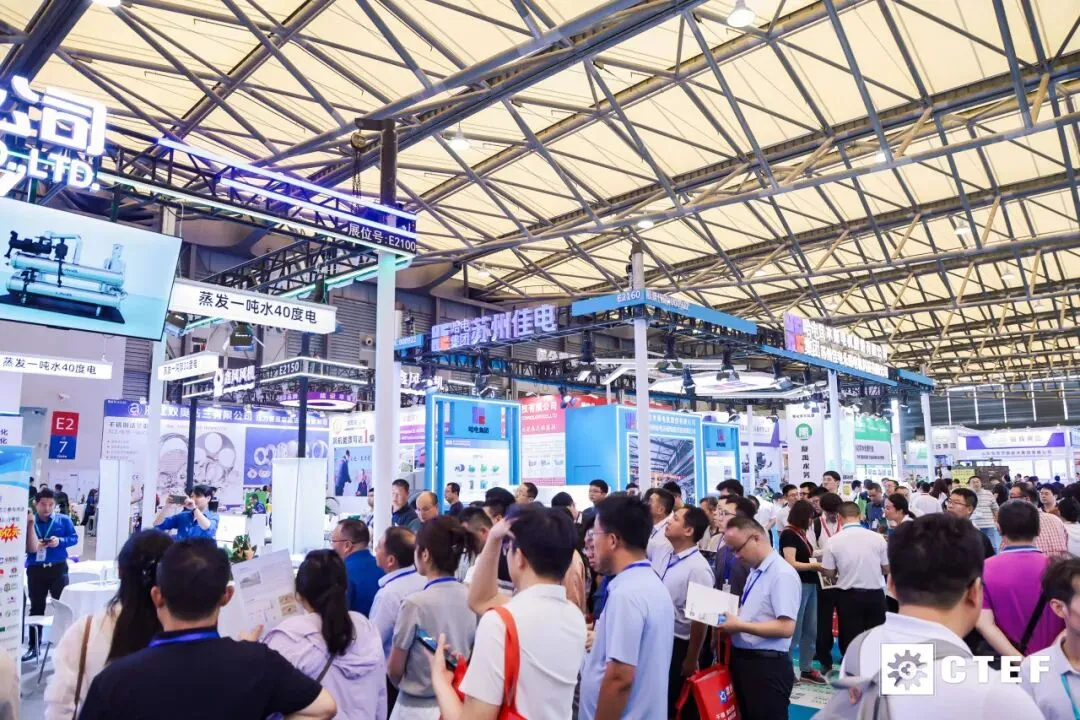

Under the triple pressures of "dual control of energy consumption, high costs, and environmental upgrades," heat pump distillation technology is becoming a key engine for the chemical industry to move towards green and high-end development. The 2026 China International Chemical Technology and Equipment Fair (CTEF), approved by the Ministry of Commerce of the People's Republic of China, will be held from June 9-11, 2026 at the Shanghai New International Expo Centre. This year's expo features a special "Heat Pump Distillation and Energy Saving Optimization Zone," which will bring together leading domestic and international companies to showcase their innovative achievements, connect with industry needs, and inject new momentum into energy conservation and carbon reduction in the chemical industry.

Traditional distillation and evaporation processes, as high-energy-consuming links in process industries such as chemical, petrochemical, and pharmaceutical, have long faced the challenges of low energy efficiency and high carbon emissions. Heat pump distillation technology, through energy cascade utilization and thermodynamic optimization, can reduce energy consumption by 30%-50%, and has become one of the most promising energy-saving and carbon-reduction pathways.

Data shows that by 2026, the penetration rate of heat pump applications in the chemical industry will increase to 28%, with equipment demand growing by more than 35%, forming a huge market worth nearly 100 billion yuan. In response to policy guidance such as the "Industrial Energy Efficiency Improvement Action Plan (2024-2026)," CTEF2026 has created a major "Heat Pump Distillation and Energy-Saving Optimization Exhibition Area," showcasing a complete chain of solutions covering heat pump main units and system integration, heat exchange and evaporation crystallization equipment, key components, intelligent control, and energy-saving services. The aim is to promote heat pump distillation from demonstration projects to large-scale applications, truly empowering the green transformation of traditional chemical industries.

Global Benchmark Companies in Heat Pump Distillation Gather

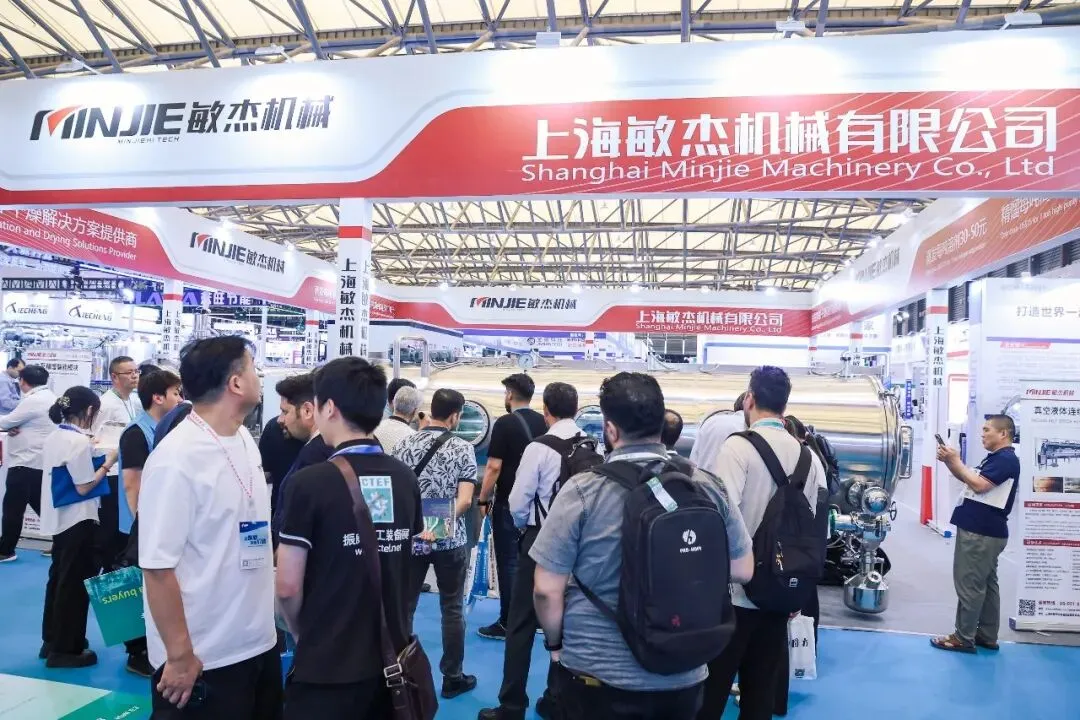

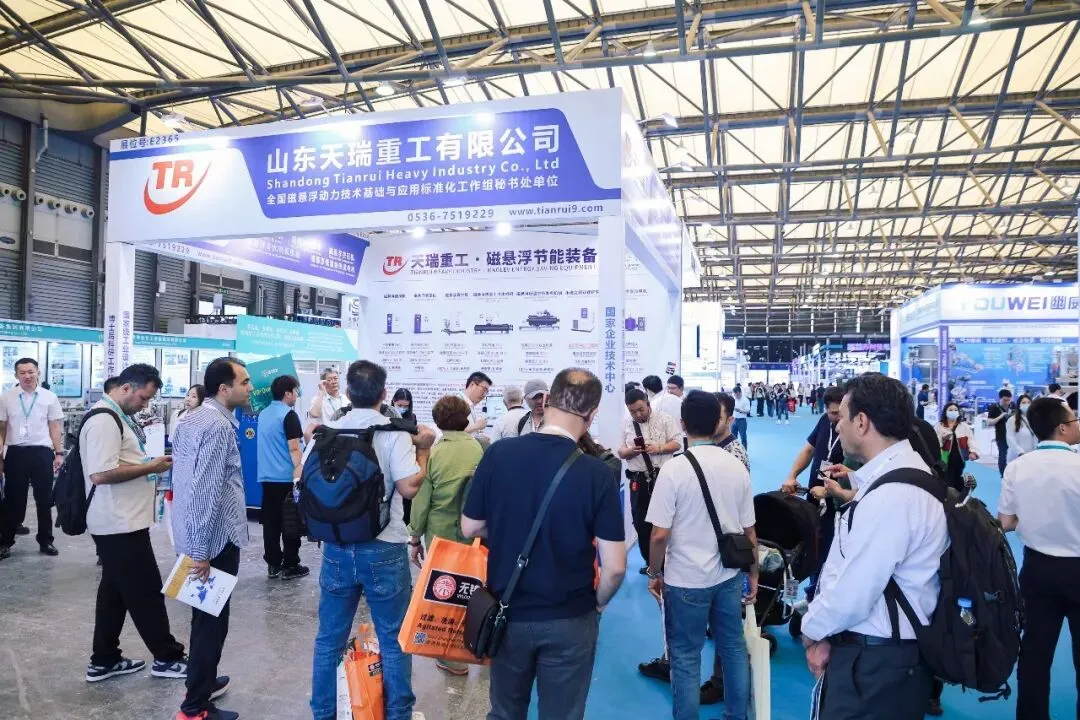

To date, the "Heat Pump Distillation and Energy Saving Optimization Exhibition Area" at CTEF2026 has attracted more than 30 leading companies in the industry, including Dison Technology, Bingshan Refrigeration & Heating, Shaanxi Blower, German Pierre, Hebei Leheng, Shanghai Minjie, Zhejiang Tianlian, Yinlun Machinery, Hekang New Energy, Tianhao Energy Saving, Dewei Turbine, Tianrui Heavy Industry, Shandong Heng Hui, Shandong Tuoton, Ningbo Lehui, Lanwang Energy Saving, Huannuo Energy, Hedun Environmental Protection, Weihai Runlan, Anhui Ruitai Technology, Datong Baofu, Shuruipu, Wuxi Jialong Electromechanical, Hairun Environmental Protection, Haomu Energy Saving, Jiangsu Feiyue, Myande Energy Saving, Jiema Energy Saving, Huashijie Environmental Protection, Yuanfang Power, Ruidin Environment, and Boxu New Energy, among other top forces in the global heat pump distillation and energy saving field. This comprehensive display showcases the diverse innovative paths of heat pump technology and provides the industry with a full-chain technical reference from core equipment to system solutions.

- Enterprises that Achieve Breakthroughs in Core Technologies

Dison Technology has achieved a major breakthrough in the field of high-temperature vapor compression heat pump technology. Its "High-Temperature Vapor Compression Heat Pump Unit" can efficiently utilize heat sources above 150℃, achieving an energy efficiency ratio (EER) of 6.0. It has been successfully applied in the high-temperature distillation processes of several chemical companies.

Pyler, a pioneer in global MVR (Medium-Vacuum Recompression) technology, presents a high-efficiency system equipped with high-temperature heat pump technology. Through the ultimate recovery and recycling of steam waste heat, it achieves a significant 50% reduction in energy consumption, providing an economical and environmentally friendly solution for high-energy-consuming processes.

Shanghai Minjie will showcase its "Ultra-Low Temperature Vacuum Concentrator" at CTEF2026. Employing heat pump technology, it achieves an EER of over 6.0, providing highly efficient and energy-saving concentration solutions for the pharmaceutical, food, and chemical industries. This product has received numerous honors, including the Shanghai High-Tech Achievement Certificate and the Shanghai Science and Technology Award, and has been successfully applied by over 500 companies both domestically and internationally, including well-known enterprises such as Shanghai Pharmaceuticals Group and Tasly Group.

Zhejiang Tianlian has divisions in biopharmaceutical and healthcare equipment, API/pharmaceutical intermediate equipment, and new energy lithium battery equipment. Its "heat pump evaporation system" utilizes heat pump technology to achieve a highly efficient and energy-saving evaporation process with an energy efficiency ratio (EER) exceeding 6.5, and has been successfully applied in the pharmaceutical, chemical, and food industries. The company holds qualifications as a National High-tech Enterprise and a "Specialized, Refined, and Innovative" Little Giant Enterprise, providing users with end-to-end heat pump evaporation system solutions from design to installation.

DeWei Turbine, as a pioneer in domestic high-pressure centrifugal compression technology, has successfully broken the "bottleneck" of long-term reliance on imported core components for heat pumps. Its products achieve internationally advanced levels in pressure ratio and energy efficiency ratio, laying a solid foundation for achieving independent control of heat pump technology.

Tianrui Heavy Industry has achieved a major breakthrough in the field of magnetic levitation centrifugal heat pump technology. Its "magnetic levitation centrifugal heat pump system" solves the stability problem of traditional heat pumps under high-temperature and high-load conditions, improving the EER by 30%, becoming a star product in the high-end heat pump market.

Shandong Heng Hui specializes in heat pump solutions for special operating conditions. Its "corrosion-resistant heat pump system" has been successfully applied to highly corrosive chemical processes, extending equipment lifespan to over 10 years. By 2025, its market share in the specialty chemical heat pump field had reached 12%, making it an emerging force in the industry.

Ningbo Lehui, through its modular skid-mounted heat pump distillation system, has achieved rapid deployment and efficient operation. It has implemented multiple benchmark projects in the petrochemical and fine chemical industries, saving over ten million yuan in operating costs annually per project, demonstrating the significant economic benefits of engineering applications.

- System Solutions Company

Bingshan Heating & Cooling, a leading enterprise in China's heat pump industry, continuously innovates in heat pump system integration. Its "multi-heat source coupled heat pump system" has been successfully applied to multiple large-scale chemical projects, achieving 55% energy savings compared to traditional processes.

Shaangu Power, leveraging its deep expertise in high-efficiency heat exchange and system optimization, provides "customized solutions" for heat pump distillation. Its independently developed "intelligent optimization platform for heat pump systems" can improve system energy efficiency by 20% and has been implemented on a large scale in companies such as CNPC and Sinopec.

Yinlun Machinery, a leading domestic heat exchange technology company, has successfully applied its "high-efficiency plate heat exchanger + heat pump system" integration solution in multiple chemical enterprises, improving energy efficiency ratio by 25% and shortening the equipment investment payback period to 2.3 years. Yinlun Machinery's heat pump systems cover more than 70% of large-scale chemical enterprises nationwide, making it one of the industry standard setters.

Hedun Environmental Protection focuses on the research and development of heat pump systems for upgrading low-grade waste heat, achieving a heat recovery efficiency of over 85%. This technology has achieved a closed-loop "zero-carbon heating" system in a large chemical enterprise in Shandong, reducing carbon emissions by 28,000 tons annually. Hedun Environmental Protection's "heat pump + waste heat recovery" system has obtained 23 national invention patents, becoming a powerful tool for chemical enterprises to achieve carbon neutrality.

Precisely Connect Global Buyers and Drive Industry Supply and Demand Matching

The Heat Pump Distillation and Energy-Saving Optimization Zone at CTEF2026 focuses on "full-chain display + precise matchmaking," leveraging CTEF's extensive buyer network to build an efficient platform connecting supply and demand in the industry.

This year's exhibition is expected to attract 100,000 professional buyers from various sub-sectors including biopharmaceuticals, fine chemicals, pesticides and fertilizers, petrochemicals, and chemical engineering. This includes purchasing decision-makers from over 100 of the top 100 chemical companies and more than 1,000 international buyer groups from over 50 countries and regions worldwide. These high-quality purchasing resources will provide exhibitors with precise business matching opportunities, directly reaching core customer groups in the industry chain, effectively expanding domestic and international markets, and achieving efficient transformation and commercialization of technological achievements.

Technical Forum Decodes New Engine for Heat Pump Distillation Development

To further promote industry exchange, CTEF2026 will concurrently host the "China Heat Pump Distillation Energy Saving Optimization Technology Forum" on June 9th. The forum will focus on key topics such as energy efficiency improvement and engineering applications of heat pump distillation systems, low-grade waste heat recovery and heat pump coupling technology, adaptation of new heat pump equipment to special chemical operating conditions, and industrialization challenges and solutions.

Technical experts from leading domestic and international companies such as BASF, Covestro, Wanhua Chemical, Lanxess, and Shaanxi Blower will be invited to share their cutting-edge practices and solutions in the field of heat pump distillation. The core audience includes decision-makers and key technical personnel from petrochemical, fine chemical, pharmaceutical, new energy materials, and energy service companies, providing a high-end platform for enterprises to connect with industry, academia, research, and application, and propelling the chemical industry towards a new stage of energy conservation, efficiency improvement, and green low-carbon development.