- Heat pump distillation · Cost reduction and efficiency improvement · Low carbon and energy saving

During the critical period of achieving "dual carbon" targets and driven by policies such as the "Industrial Energy Efficiency Improvement Action Plan (2024-2026)," the chemical industry faces triple pressures: "dual control of energy consumption + high costs + environmental upgrades." Traditional distillation and evaporation processes account for over 40% of the industry's total energy consumption. Heat pump distillation, with its core advantages of "tiered energy utilization + efficient waste heat recovery," has become the core engine for carbon reduction in the industry. Technological breakthroughs and large-scale applications directly determine a company's low-carbon competitiveness.

Data shows that the market size of China's chemical energy-saving equipment will exceed 90 billion yuan in 2025, and the demand for heat pump distillation related equipment will grow by more than 35%. In 2026, the penetration rate of heat pump applications in the chemical industry will increase to 28%, and the Asia-Pacific region will become the core application and innovation source.

The 2026 China International Chemical Technology & Equipment Fair (CTEF2026), approved by the Ministry of Commerce of the People's Republic of China, will be held from June 9-11, 2026 at the Shanghai New International Expo Centre. This year's expo features a dedicated heat pump distillation and energy-saving optimization exhibition area, and will concurrently host the Chemical Heat Pump Distillation Energy-Saving Optimization Technology Forum. The forum will focus on in-depth discussions of hot topics such as breakthroughs in core heat pump technologies, energy-saving retrofitting of distillation processes, deep utilization of waste heat resources, and the construction of zero-carbon industrial parks. Benchmark case studies will also be shared, comprehensively showcasing the industry's latest technological achievements and solutions in high-efficiency energy saving, intelligent manufacturing, and low-carbon collaboration, helping the industry move towards high-end, intelligent, and green development!

Part1

Focusing on Four Core Breakthroughs to Build an Energy-Saving Innovation Ecosystem

The Heat Pump Distillation and Energy-Saving Optimization Exhibition Area at CTEF2026 focuses on four key breakthrough directions for industrial transformation, creating an innovative display and matchmaking platform covering the entire industry chain.

- Breakthrough in the ultimate utilization of thermal energy

For high-energy-consuming processes such as chemical distillation, evaporation, and drying, the exhibition area focuses on showcasing core equipment such as high-temperature steam compression heat pumps, magnetic levitation centrifugal heat pump units, and low-grade waste heat upgrading systems. Combined with key components such as high-efficiency heat exchange tubes and corrosion-resistant heat exchangers, the system's energy efficiency ratio (COP) can reach up to 7.2, saving 50%-70% energy compared to traditional processes. This helps companies break through energy consumption bottlenecks and achieve the dual goals of "ultimate energy saving + economical operation".

- System integration and modular upgrade

Addressing the pain points of chemical enterprises—limited space, short renovation cycles, and complex operation and maintenance—the exhibition area focuses on modular and skid-mounted solutions, showcasing innovative products such as complete skid-mounted heat pump distillation equipment, integrated evaporation crystallization systems, and mobile waste heat recovery devices. Through standardized design, factory prefabrication, and on-site assembly, the project construction cycle is significantly shortened (by more than 40% compared to traditional projects), reducing on-site construction costs and operation and maintenance difficulties, providing the optimal solution for energy-saving renovations for small and medium-sized chemical enterprises—one that is "low-cost and quick to implement."

- Intelligent control and precise innovation

Leveraging cutting-edge technologies such as AI and digital twins, the exhibition area showcases intelligent equipment including a heat pump distillation AI controller, a multivariate predictive control system, and a cloud-edge collaborative energy efficiency management platform. By monitoring energy consumption data in real time, dynamically optimizing operating parameters, and predicting equipment failure risks, these systems enable a shift from "passive operation and maintenance" to "proactive control" and "predictive maintenance." The intelligent crystallization control system, in particular, can control product purity fluctuations within ±0.5%, reducing equipment failure rates by 30%, and bringing enterprises triple value: precise temperature control, stable operation, and cost reduction and efficiency improvement.

- Low-carbon collaborative whole-chain construction

The low-carbon transformation of industries is upgrading from "single-equipment energy saving" to "whole-chain collaborative carbon reduction." The exhibition area focuses on showcasing solutions such as online carbon emission monitoring systems, phase change energy storage and heat pump coupling devices, and integrated wastewater treatment and waste heat recovery systems. Through a full-chain service of "energy-saving equipment + environmental governance + carbon asset management," it helps enterprises deeply integrate energy conservation and carbon reduction with production and operation, achieving a win-win situation of "reduced energy consumption + reduced carbon emissions + resource recycling," and assisting chemical enterprises in creating zero-carbon demonstration benchmarks.

Part 2

Precisely connecting 100,000 buyers to drive supply and demand matching in the industry

The Heat Pump Distillation and Energy Optimization Zone at CTEF2026 focuses on "full-chain display + precise matchmaking." It not only presents complete solutions from core components to integrated systems, and from manufacturing testing to engineering services, but also leverages CTEF's powerful buyer resource network to build an efficient platform connecting the supply and demand sides of the industry.

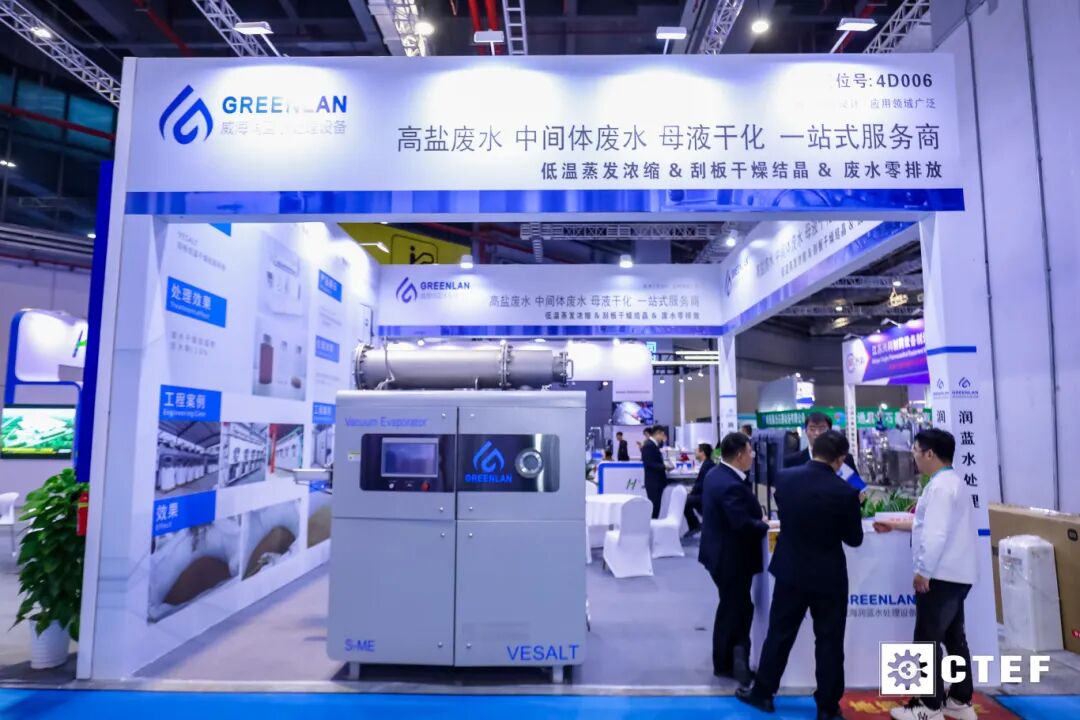

This year's exhibition is expected to attract 100,000 professional buyers from various sub-sectors including biopharmaceuticals, fine chemicals, pesticides and fertilizers, petrochemicals, and chemical engineering. These include purchasing decision-makers from over 100 of the top 100 chemical companies and more than 1,000 international buyer groups from over 50 countries and regions worldwide. These high-quality purchasing resources will provide exhibitors with precise business matching opportunities, allowing them to directly reach core customers in the industry chain, effectively expand into domestic and international markets, and achieve efficient transformation and commercialization of technological achievements.

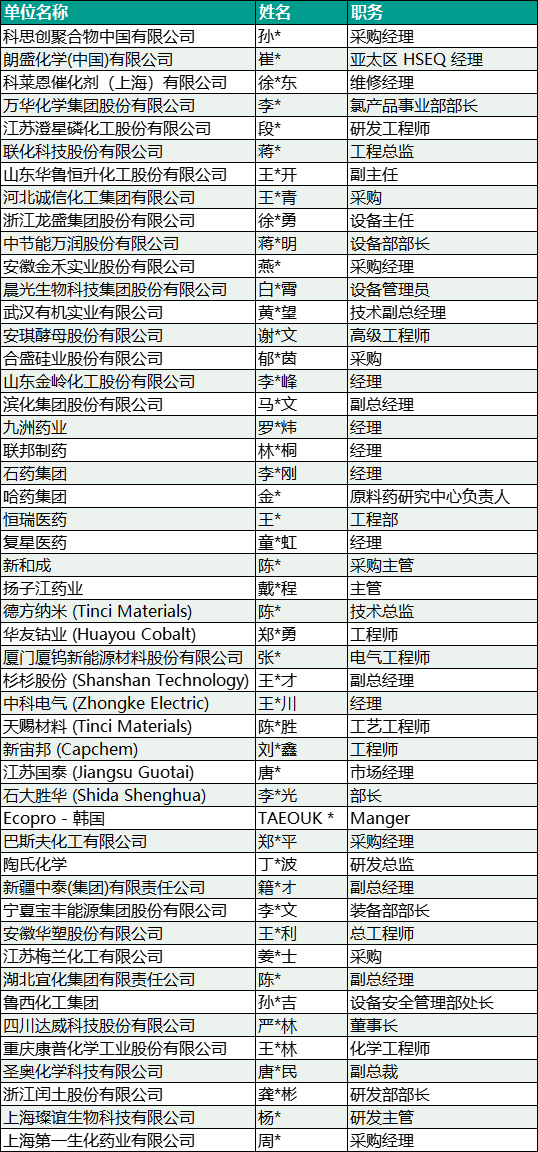

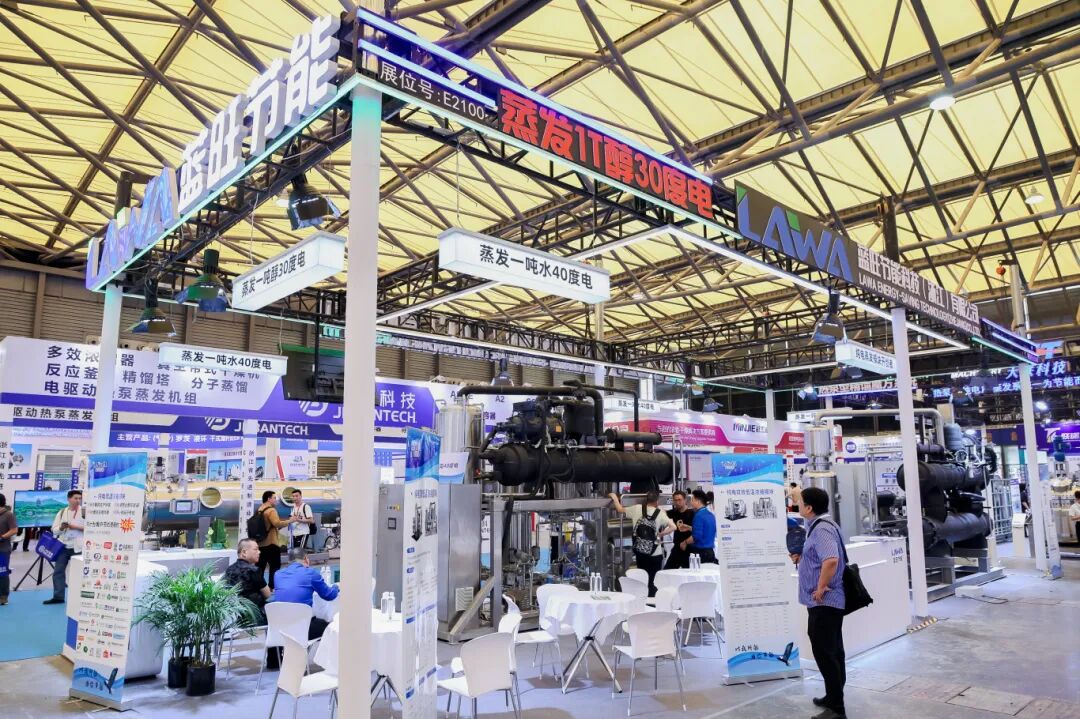

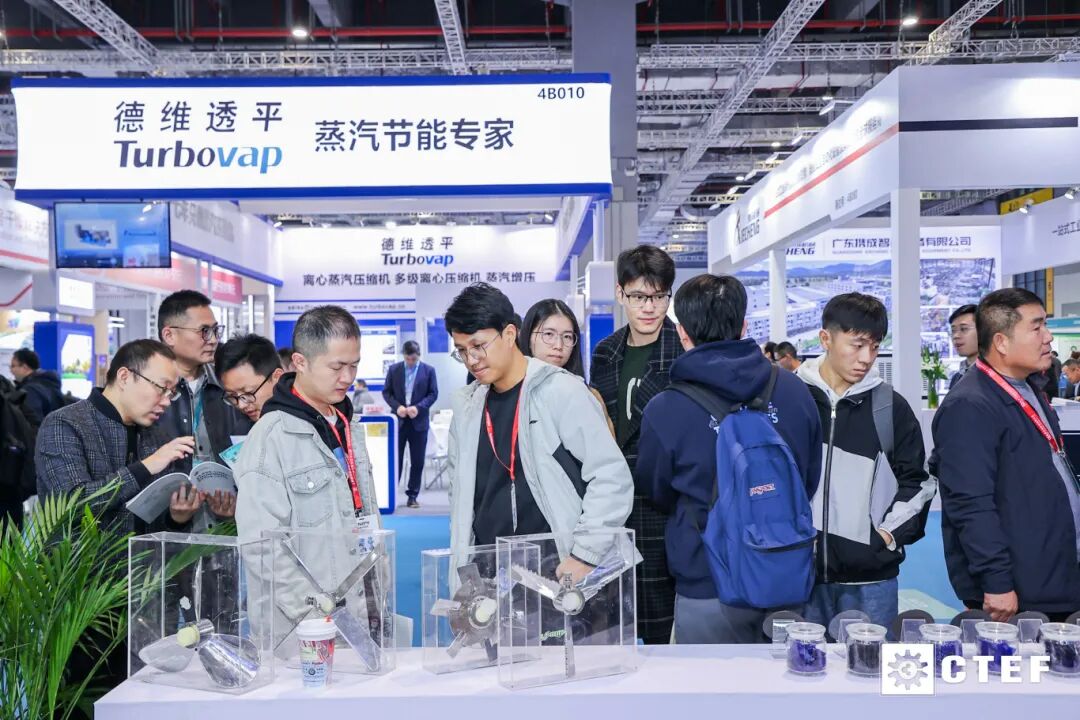

- Global benchmark companies for heat pump energy saving gather

To date, CTEF2026 has attracted top global players in heat pump distillation and energy conservation, including Dison Technology, Bingshan Refrigeration & Heating, Shaanxi Blower, Yinlun Machinery, Hiconics, Tianhao Energy Saving, Devi Turbine, Tianrui Heavy Industry, Shandong Heng Hui, Shandong Tuoton, Ningbo Lehui, Lanwang Energy Saving, Huannuo Energy, Hedun Environmental Protection, Weihai Runlan, Anhui Ruitec, Datong Baofu, Shuruipu, Wuxi Jialong Electromechanical, Hairun Environmental Protection, Haomu Energy Saving, Jiangsu Feiyue, Myande Energy Saving, Jiema Energy Saving, Huashijie Environmental Protection, Yuanfang Power, Ruidin Environment, and Boxu New Energy. It comprehensively showcases the diverse innovation paths of heat pump technology and, through their respective leading advantages, provides the industry with a full-chain technical reference from core equipment to system solutions.

◆ Devi Turbine, through its technological breakthrough in domestically produced high-pressure centrifugal compressors, has broken through the long-standing bottleneck of relying on imports for core heat pump components. Its products achieve internationally advanced levels in pressure ratio and energy efficiency ratio, powerfully promoting independent control over core technologies.

◆ Shurepu, a global leader in heat exchange technology, offers plate/spiral plate heat exchangers with high-efficiency heat transfer and corrosion resistance, making them a key component for energy saving and efficiency improvement in heat pump systems.

◆ Ningbo Lehui's skid-mounted heat pump distillation system, through modular design, enables rapid deployment and has accumulated multiple benchmark cases in the petrochemical and fine chemical industries, saving over ten million yuan in operating costs annually.

◆ Hedun Environmental's low-grade waste heat upgrade heat pump system enables deep recovery of waste heat from flue gas and wastewater, helping enterprises achieve a closed-loop "zero-carbon heating" system.

Part 3

Durch die Zusammenführung modernster Technologien und Ausrüstungen werden die Bedürfnisse der gesamten Wertschöpfungskette abgedeckt

The CTEF2026 Heat Pump Distillation and Energy Saving Optimization Zone will bring together leading domestic and international companies, showcasing a wide range of products and services.

- Heat pump unit and system integration

• Industrial heat pump units: High-temperature vapor compression heat pumps, absorption heat pumps, magnetic levitation centrifugal heat pumps, air source/ground source/water source industrial heat pump units.

• Heat pump distillation integrated systems: Mechanical vapor recompression (MVR) distillation systems, heat pump-multi-effect distillation coupling devices, azeotropic distillation heat pump energy-saving systems, skid-mounted heat pump distillation complete sets of equipment.

- Heat exchange and evaporation crystallization equipment

• High-efficiency heat exchange equipment: Plate/shell-and-tube/spiral plate heat exchangers, microchannel heat exchangers, graphite/titanium/zirconium corrosion-resistant heat exchangers, falling film evaporators/reboilers/condensers.

• Evaporation crystallization systems: MVR mechanical compression evaporation crystallization systems, externally heated circulating evaporators, vacuum crystallizers/OSLO crystallizers, zero-discharge evaporation systems for high-salt wastewater.

• Drying equipment: Rotary dryers, belt dryers, rotary flash dryers, paddle dryers.

- Key components and special materials

• Core components of the heat pump: High-pressure centrifugal compressor/screw compressor, high-temperature electronic expansion valve/corrosion-resistant valve, high-efficiency heat exchange tubes/bellows/threaded tubes.

• Power and transmission equipment: Roots blower/centrifugal blower, industrial computer and PLC control system, frequency conversion technology and drive system.

• Special materials and accessories: Titanium/Hastelloy/duplex stainless steel materials, fluoroplastic-lined corrosion-resistant equipment, high-performance sealing and insulation materials.

- Manufacturing Inspection and Intelligent Control

• Manufacturing and processing equipment: Laser welding equipment/automatic tube expander, tube end forming machine/tube bending machine, automated heat exchanger production line.

• Testing and monitoring system: Online performance monitor (COP real-time monitoring), PHM fault prediction and health management system, sealing performance test bench.

• Intelligent control system: Heat pump distillation AI energy-saving controller, multivariable predictive control algorithm module, cloud-edge collaborative energy efficiency management platform.

- Energy-saving optimization and supporting services

• Waste Heat Recovery Systems: Upgrading low-grade waste heat to heat pump systems, deep waste heat recovery devices for flue gas/wastewater, phase change energy storage tanks/high-temperature thermal storage systems.

• Environmental Protection Collaborative Equipment: Wastewater treatment and reuse devices, falling film condensate recovery systems, online carbon emission monitoring systems.

• Engineering Service Solutions: Thermal energy system optimization design services, energy-saving retrofitting and energy performance contracting, full life-cycle operation and maintenance support.

Part 4

Exhibition booths are running out! Seize the golden window of opportunity for low-carbon transformation

The CTEF2026 Heat Pump Distillation and Energy-Saving Optimization Exhibition Area serves as a core platform for showcasing and exchanging innovative achievements in the global chemical industry's energy conservation and low-carbon sector. Exhibitors will deeply integrate into the industry's innovation ecosystem, directly address cutting-edge technological trends, connect with precise business opportunities, share CTEF's global resource network, and explore broader market opportunities. The concurrently held Chemical Heat Pump Distillation Energy-Saving Optimization Technology Forum will further build a high-level bridge for enterprises to interpret policies, discuss technologies, and connect supply and demand, helping them seize the commanding heights of industry development.

With the accelerating release of demand for energy-saving renovation and green transformation in the chemical industry, high-quality exhibition booths in this year's exhibition area are becoming increasingly scarce. Booth reservations are now in a critical stage; please contact the organizing committee to secure your participation rights. Let us work together to propel heat pump distillation and energy-saving optimization technologies to new heights and create a green and intelligent future for the industry!