From June 9th to 11th, 2026, the annual China International Chemical Technology & Equipment Fair (CTEF) will be held at the Shanghai New International Expo Centre.

SUZHOU AODE PRECISE EQUIPMENT Co., LTD. will showcase its cutting-edge equipment and products at booth E1640. We welcome industry professionals from home and abroad to visit our booth for exchange, and to discuss procurement cooperation.

- Company Profile

Founded in Shenzhen in 2004 and headquartered in Suzhou in 2007, Aode has always focused on the industrial temperature control field, and is a temperature control equipment manufacturer integrating R&D, production, and sales. After 21 years of innovative development and accumulation, Aode's products have evolved from a single heating series to a comprehensive product matrix encompassing heating, cooling, integrated heating and cooling systems, and centralized cooling and heating, enabling it to provide diversified and customized temperature control product solutions for various industries. Currently, it has eight major production bases in East and South China, and sales and service centers in Tianjin, Jinan, Qingdao, Anhui, Chongqing, Thailand, Vietnam, Indonesia, Mexico, and Russia.

- Enterprise Products

- Thermal oil heating device

- Explosion-proof device, air blowing and oil return function, shutdown delay cooling function (optional);

- RS485 communication function for automated management (optional);

- Isolated electrical control box to extend the service life of electrical components;

- Pipeline uses dedicated piping for organic heat carrier boilers;

- Comprehensive safety protection with intelligent fault display;

- Designed according to the standards of organic heat carrier boilers, with hot oil BY-PASS pressure relief;

- Control method: Imported microcomputer or (optional) PLC control.

- TCU temperature control unit

The Aode TCU temperature control system utilizes the client's public utility heat and cold sources (primary system) to supply heat and cold to the TCU temperature control system (secondary system). The secondary system then precisely controls the temperature of the process system, ensuring that only one heat transfer medium exists in the reactor jacket. Cascade control is employed for precise and rapid calculation and control of the entire reaction's temperature changes. It can accurately and quickly respond to both endothermic and exothermic reactions throughout the process, and the DCS enables intelligent IoT control of the entire plant.

- High and low temperature integrated temperature controller

- Featuring a high-strength, integrally welded frame, with liquid-contact parts constructed from seamless SUS304 stainless steel;

- Local color LCD touchscreen display supporting local/remote operating mode switching;

- Equipped with a variable frequency pump, supporting a wide range of adjustable output flow and pressure, with a flow accuracy of +0.2L/Min;

- Comprehensive safety protection functions, including power phase sequence, high and low voltage, motor overload, low liquid level and over-temperature protection, and anti-freeze protection;

- Core components such as the compressor are sourced from leading international brands;

- Equipped with remote communication capabilities, supporting RS485 and CAN communication;

- Stable unit operation, high temperature control accuracy, and rapid heating and cooling rates;

- Temperature control accuracy ±1℃;

- Equipped with casters for easy movement; simple installation, operation, and maintenance.

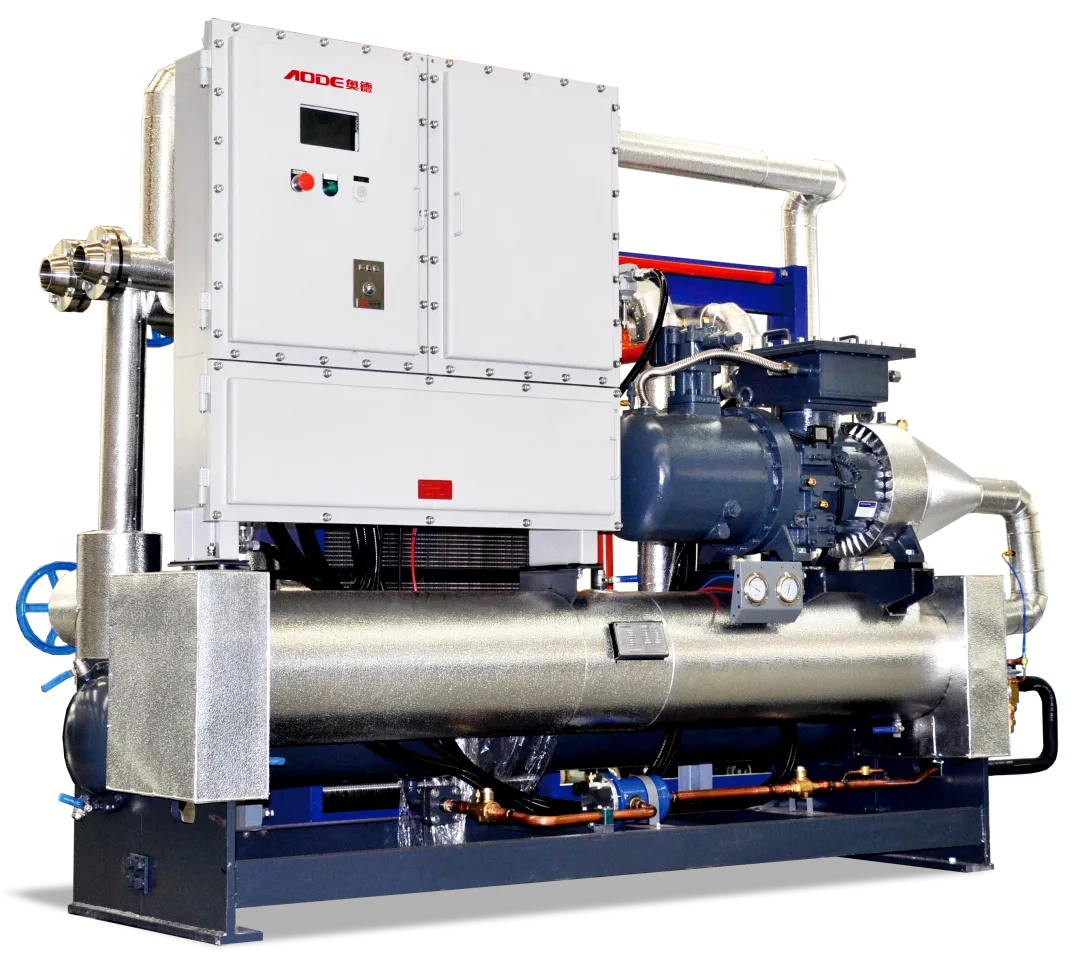

- Screw chiller

- The unit features comprehensive protection functions; an ExdlIBT4 explosion-proof model is available upon request.

- Refrigeration valves are sourced from renowned brands such as Danfoss, Emerson, and Sporlan.

- Electrical components are sourced from renowned brands such as ABB, Siemens, and Schneider Electric.

- Standard configuration includes a remote start/stop interface and a comprehensive fault transmission interface.

- Refrigerant options include R22, R407C, R404A, and R134A.

- Evaporators are available in acid and alkali resistant and corrosion-resistant types.

- Gas-fired organic heat carrier boiler

- Both front and rear furnace doors can be quickly opened for rapid inspection and maintenance;

- Equipped with a viewing window for clear monitoring of combustion;

- Features an explosion-proof vent to prevent deflagration during furnace ignition and provide timely pressure relief—a feature typically absent in other boilers;

- Optimal heat transfer tube diameter design ensures appropriate film temperature and sufficient heat coal quantity and flow rate, extending tube life and slowing down medium oil degradation;

- In addition to ceramic fiber and refractory mortar insulation on the inner surface, the boiler door cover is reinforced with rock wool insulation to minimize heat loss and provide a good operating environment;

- Three-layer boiler shell insulation: inner ceramic fiber, middle rock wool board, and outer lightweight cement to reduce heat loss and increase external strength;

- Three-loop tube design provides approximately 30% more heat transfer area than typical medium-pressure boilers on the market, reducing flue gas temperature and significantly improving boiler efficiency;

- Large combustion chamber prevents flame contact with tube walls, reducing nitrogen oxide emissions.

- Certificate of Honor

The company is a national-level specialized and innovative "little giant" enterprise, a national-level high-tech enterprise, a Jiangsu Province specialized and innovative enterprise, a Jiangsu Province science and technology enterprise, a Jiangsu Province genuine product commitment enterprise, a Jiangsu Province green factory, a Jiangsu Province industrial enterprise quality credit A-level enterprise, a Jiangsu Province science and technology enterprise listing cultivation plan entry, and a Jiangsu Province high-precision intelligent temperature control machine engineering technology research center, etc., including Class B boilers, TUV certification, CE certification, ISO9001, ISO4001, and ISO45001 quality management system certifications.